Hook and Cable Lifts

Whether you’re looking for maximum versatility, fast turnaround between jobs, or heavy-duty performance, our hooklift and cable hoist solutions are built to meet the needs of waste hauling, construction, landscaping, and municipal fleets. We upfit and distribute top brands like Stellar Industries, Palfinger, and Switch-N-Go.

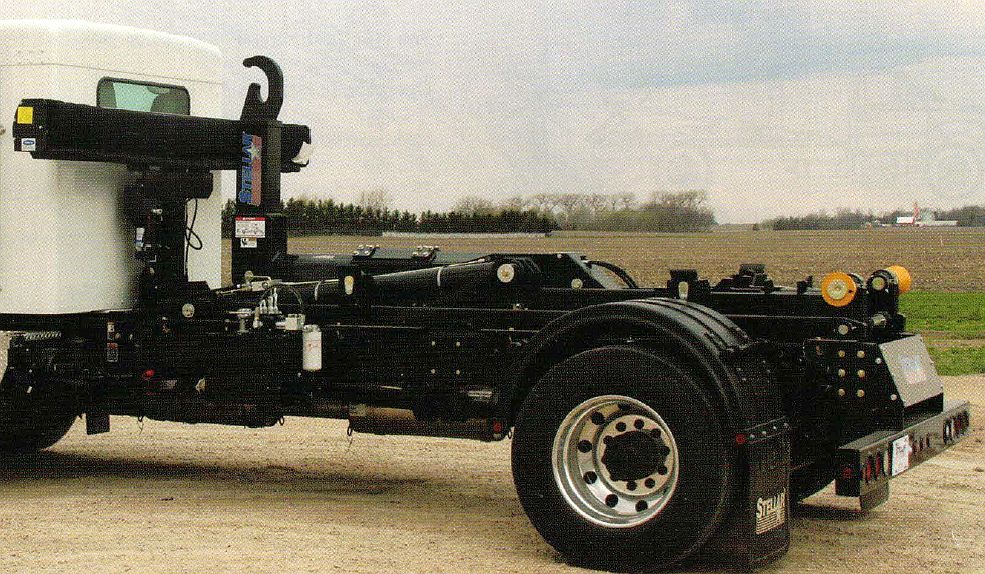

Stellar Industries

Known for their rugged design and unmatched reliability , Stellar hooklift systems deliver the performance you need for demanding jobs.

Key Features:

- Multiple hook heights for fleet compatibility

- Full-length dump frame support

- Hydraulic and electronic control systems

- Capacities ranging from light-duty to 65,000 lbs

Shuttle Series Hooklifts

Designed for simplicity, durability, and one-operator use, this is the only U.S.-manufactured Shuttle-type hooklift line.

- Models: Shuttle16 (Flex), Shuttle20, Shuttle24, Shuttle32, Shuttle34, Shuttle40, Shuttle52, and Shuttle65 — capacities ranging from 16,000 lb up to 65,000 lb Stellar.

Highlights: Cable-free design using two independently controlled hydraulic cylinders, in-cab operation only, low operator training needs, and robust use for recyclers, landscapers, municipalities, dump body operations, etc.

Slider50 / Slider65: Historically offered at 50K and 65K, now being phased out in favor of the newer NXT model

Slider Series Hooklifts

General Design & Features:

The Slider Series introduces a telescopic sliding jib for adjustable hook heights—manual or hydraulic—with hook bar heights from 35.6″ to 61.75″, accommodating a wide variety of body lengths without needing multiple container fleets. They use a mechanical dump interlock system, full-length dump frames with continuous rollers, greaseable bushings, and standard low-flow/high-pressure hydraulics with power‑beyond ports for accessories

- Slider20 / Slider20‑S: 20,000 lb capacity with sliding hook jib, strong flexibility in body lengths.

- Slider26: ~30,000 lb capacity with extended hook rise.

- Slider34: Up to 34,000 lb capacity, manual/hydraulic hook adjustment.

- Slider40: Up to 40,000 lb capacity.

Model Capacities: NXT18, NXT24, NXT30, NXT40, NXT52, NXT68—covering from light to ultra-heavy capacity requirements.

NXT™ Series Hooklifts

General Design & Innovations:

Stellar’s latest telescopic line, offering best‑in‑class features for performance, serviceability, and versatility. The NXT Series is based on a Z‑rail telescopic design, with lightweight yet structurally strong components, bolt‑on universal body locks, integrated wear pads, and industry‑leading low lost‑load heights (NXT18: ~7.5″, NXT40/52: ~10.5″)

Highlights per Feature:

- Adjustable Hook Height: NXT18 (manual 36–54″); NXT40/NXT52 (manual + hydraulic 54–62″).

- Cycle Efficiency: Soft‑stop feature gently halts the body on saddles; speed‑enhancement can cut cycle times up to 75%.

- Controls & Operation: NXT18 uses electronic controls with two‑speed operation; NXT40/52 offers an air‑control system and handheld remote.

- Reservoir Flexibility: Hydraulic reservoirs (8‑gal NXT18; 25‑gal NXT40/52) can be mounted at bulkhead or along chassis/frame to accommodate different installations.

Stellar Flex36 Hooklift Hoist

Shuttle16 Hooklift (FLEX 36-84) Details:

– Dump Angle: 53˚

– Effective Length: 115″ (2,921 mm)

– Cab to Axle: 84″ – 96″ (2,134 – 2,438 mm)

– Lifting/Dumping Cap: Up to 16,000 lbs (7,257 kg)

– Weight: 1,360 lbs (617 kg)

– Rec. Body Lengths: 10′ – 12′ (3,048 – 3,658 mm)

– Hook Heights: 35.63″ (905 mm)

– Min. Truck GVWR: 10,500 – 26,000 lbs (4,763 – 11,793 kg)

Key Features: The Shuttle16 maintains all of Stellar’s efficient operational and mechanical features such as the in-cab controls and body locks to ensure stability and secure attachment. All Stellar Hooklifts feature permanently lubricated greaseable bushings, zinc-plated pins and an efficient low-flow, high-pressure hydraulic system.

Base Section: The base section may also be called a subframe. All Stellar Hooklift hoists are tied together in one common framework. This base section not only adds strength to the hoist but also places less stress concentration on the truck chassis by providing additional structural support. The base section also provides for simple installation on most truck chassis.

Body Latch: The body latch is also referred to as the rear tiedown. Standard on Stellar Hooklift hoists are the rearward-facing hooks that interface with a horizontal steel pocket or tab. As the body is pulled forward into the final storage position prior to transporting, the tabs will pull tight in the hook pockets. Hydraulic-activated rear tiedowns are optional on larger Stellar Hooklift hoists.

Dump Section: This component of the Stellar Hooklift pivots at the rear of the hoist and when the tilt engages the patented dump latch tabs, allowing for the container dumping function. The rear-body latches are attached to this component on all models, allowing the body to remain in the latches while in transit and dumping.

Front Saddles: Front saddles provide a place for the body to rest while the truck is in motion.

Lift Cylinder: The lift cylinder lifts the body onto the truck and provides the dumping movement. All Stellar Hooklift lift cylinders feature dual pilot-operated counterbalance valves which provide optimum meter-ability and protection against sudden movement in the case of hose failure.

Tilt and Dump Latch: This unique patented feature is the basis of the Stellar Hooklift system. With a simple mechanical engagement between the tilt section and the dump section, the pivot point is changed from the secondary section (loading/offloading) to the rear of the truck (dumping). Resettable tabs protect the system from out-of-sequence operation.

Rear Rollers: With the unique Stellar Hooklift design, bodies are loaded and unloaded with a lift and roll movement. While unloading a body, the tilt section will lift the front of the body and roll it back. The tilt cylinder will continue rolling the body until the rear of the body contacts the ground.

Plunger Valve: The plunger valve will lock out all hydraulic fluid to the tilt cylinder when in the dumping mode to prevent the accidental release of the body while dumping.

Secondary Section: The secondary section acts as the main pivoting member for loading/offloading bodies. This component ties the tilt and dump sections together into one cohesive unit.

Tilt Cylinder: The tilt cylinder operates the tilt section of the Stellar Hooklift and features a pilot-operated counterbalance valve on both extend and retract sides. With Stellar’s unique twin post design, line-of-sight visibility of the hook is available from the truck cab.

Stellar Slider-20-S SlidingJib Hooklift Hoist

Shuttle16 Hooklift (FLEX 36-84) Details:

– Dump Angle: 53˚

– Effective Length: 115″ (2,921 mm)

– Cab to Axle: 84″ – 96″ (2,134 – 2,438 mm)

– Lifting/Dumping Cap: Up to 16,000 lbs (7,257 kg)

– Weight: 1,360 lbs (617 kg)

– Rec. Body Lengths: 10′ – 12′ (3,048 – 3,658 mm)

– Hook Heights: 35.63″ (905 mm)

– Min. Truck GVWR: 10,500 – 26,000 lbs (4,763 – 11,793 kg)

Minimize operational and maintenance costs, maximize efficiency of your fleets — and benefit your business. The Stellar Slider Series Hooklift is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with a wider range of lengths with the use of a sliding jib.

Proven Performance: As part of the largest line of hooklifts in North America, Stellar Slider Series Hooklift Trucks are known for their versatile design and ease of operation and popularity in a variety of industries. Available with manual or hydraulic adjustable hook heights, Stellar Slider Hooklift Trucks can handle 35.63″ (905 mm) to 61.75″ (1,568 mm) hook height bodies and can accommodate capacities from 20,000 lbs (9,072 kg) to 65,000 lbs (29,484 kg).

All models of Stellar’s Slider Hooklift Trucks feature permanently lubricated and greaseable bushings, a mechanical dump interlock system and an efficient low-flow, high-pressure hydraulic system with standard power beyond port to provide hydraulics to other accessories.

Stellar Slider Hook Lift Trucks provide a full-length dump frame and rollers positioned throughout the loader, instead of saddles with wear pads. Each and every Stellar Hooklift Truck operates using in-cab controls, which allow for metering of the hydraulic valve while offering a clear view of the operation through the rear window.

Additionally, any Stellar Slider Hooklift Truck will accommodate various lengths of bodies and still attain the maximum rated dump angle. The mechanical rear body latch system will match a multitude of different body hold down configurations and ensure body stability when in transit.

Safety Matters: When you’re responsible for handling heavy loads, it goes without saying that efficiency is a must. With Stellar Slider Series Hook Lift Trucks, you can load, unload and change bodies with ease and efficiency — and without leaving the comfort of the truck cab. Faster loading and unloading and reduced risk of injury are major benefits of a Stellar Slider Hooklift Truck, as operators are not exposed to moving machinery when operating controls or hooking up heavy cables on muddy, snowy, wet or other slippery and hazardous surfaces.

20,000-lb Capacity Sliding Jib Hooklift:

Discover how the Stellar® Slider20-S Hooklift can make your day-to-day operations more efficient. The Slider20-S is a body handling system mounted on a truck chassis that is capable of loading, unloading and dumping various bodies with lengths ranging from 10′ (3.0 m) to 14′ (4.2 m) with the use of a sliding rectangular jib. The rectangular jib reduces flex and provides greater structural integrity. The Slider20-S can accommodate capacities up to 20,000 lbs (9,071 kg). The maximum dump angle is 60° with all hook heights.

The Slider20-S is equipped with a telescopic jib and is available with 35.63″ (905 mm) or 54″ (1,372 mm) hook heights that are adjustable either manually or hydraulically to allow for working with various length and hook height containers.

Key Features: Will accommodate bodies from 10′ up to 14′ long and still retain the maximum rated dump angle on a 40″-high frame truck. Longer bodies may be accommodated with reduced dumping capabilities. – Will accommodate various hook heights on containers with adjustable hook heights jibs, either with manual adjustable hook heights or hydraulic hook heights. – Transmission-mounted PTO and hydraulic pump required to power the hooklift. – Standard in-cab manual controls allow for metering of the manual hydraulic valve. – 25-gallon, frame-mounted oil tank.

– Operating pressure is 4,500 psi.

– Hydraulic flow required is 24 gallons per minute.

– Valve bank equipped with power beyond port.

– Mechanical dump/load interface.

– Hydraulic counterbalance valves to prevent cylinder collapse in case of hose failure.

– Inside or outside bolt-on, slide-through, rear-body tiedown latches.

– Plunger valve to prevent front jib movement when the dump frame is raised.

– Permanently lubricated and greaseable bushings used throughout.

– Grease zerks at all pinpoints to allow purging of contaminants.

– Carbon steel and zinc-plated or type 17-4 stainless-steel pins used throughout.

– All weldments painted with two-part polyurethane enamel.

Additional Features:

Base section: The base section of a Stellar Slider may also be called a subframe. All Stellar Slider Hooklifts are tied together in one common framework. This base section adds strength to the loader and places less stress concentration on the truck chassis by providing additional structural support. The base section provides for simple installation on most truck chassis.

Latches: Inside and/or outside bolt-on latches for ease of installation and replacement.

Jib/Secondary: The sliding jib allows for a wider range of container lengths and a means to control the truck’s weight distribution while remaining in the latches. The jib and secondary booms are rectangular shaped for structural integrity. The jib is equipped with an adjustable hook height, either hydraulic actuated or manually adjustable, to allow for picking of various size containers.

Wear pads: Easily replaceable wear pads for the jib/secondary boom assemblies can be changed in minutes and ensure long life for the jib/secondary assemblies. It’s not necessary to disassemble the hooklift to replace wear pads.

Dump section: Dumping is accomplished through the rear pivot point. Jib and dump sections must lock together to support the full length of container/body when in the dump mode.

Skid rollers: These three sets of rollers allow skid to roll freely forward and backward while operating the jib. They prevent long sills from wearing prematurely by not dragging steel on steel, and they eliminate the need to replace wear pads on base frame.

Bushings and zerks: Bushings and grease zerks at all pivot points.

Counterbalance valves: Counterbalance valves are used on all cylinders, protecting both extend and retract functions in case of a hydraulic hose failure.

Pins: Carbon-steel and zinc-plated or type 17-4 stainless steel to prevent corrosion.

Palfinger

A global leader in lifting and loading solutions, Palfinger delivers innovative equipment designed for efficiency, safety, and versatility.

Key Features:

- Innovative sliding hooklift systems

- High lifting and dumping angles

- Flexible container length compatibility

- Advanced control and safety features

Palfinger’s hooklift product line offers solutions for moving containers across waste, construction, scrap, and rental sectors. Notably, their HT 500 model leads the line in North America:

- HT 500 – heavy‑duty hookloader with up to 50,000 lb capacity, telescopic jib, remote control, soft‑stop system, low‑profile stability design

Palfinger Hooklift Models

Internationally, Palfinger lists the following hooklift variants by container length, hook height, and GVWR capability.

- City – compact single‑hook (~7.5 t GVWR), hook height ~3–4.3 m, container lengths near 3–4 m.

- PHT Series (e.g. PHT 12 and PHT 22) – higher lift/telescoping capabilities, single hook, container lengths ~11–15 t GVWR.

- HAD Series (HAD 185, 200, 250, 300) – robust units, multiple configurations; multi‑GVWR, hook heights up to ~7 m, supporting up to ~24 t containers.

- HT Series (HT 400, HT 500, HT 660) – heavy‑duty multi‑hook units, for large container lengths up to ~29 t GVWR.

- T Series such as T 29 – multi‑hook for medium GVWR ~7.5 t.

HT 160 and others in the HT family covering intermediate capabilities

Palfinger Cable Hoist Models

Palfinger manufactures roll‑off cable hoists in the U.S. under the American Rolloff brand. Capacity ranges from 12,000 to 75,000 lbs with multiple mounting styles

- ARH (American Roll‑Off Heavy‑Duty) – up to 75,000 lb capacity, 24 ft length, heavy‑duty applications.

- ART (American Roll‑Off Top Mount) – frame‑clearance design, top‑mount configuration.

- ARD (American Roll‑Off Direct Mount / Basic Mount) – low‑clearance or frame‑mount variants.

- Multiple mounting series: Heavy‑Duty, Standard Application, Low Clearance, Frame Clearance – each covers varying vehicle and container setups

Switch-N-Go

Hoist System Models

E‑Series (Medium‑Duty Electric‑Over‑Hydraulic)